Elasticity – an introduction

The word “Elastic” is something most people understand best by a RUBBER BAND or strap in our dress, such materials rebound to its original shape after getting stretched , and using just hand force.

What is the definition of Elasticity ? And Plasticity?

Elasticity is a property of any material which enables the material to return to its original form after the external force is removed.

So, if the material does not return to its original form like length, or volume, it is not elasticity.

Difference between Elasticity and Plasticity? In Plasticity, the material gets permanently deformed and cannot return to its original form.

Are metals elastic like a rubber band?

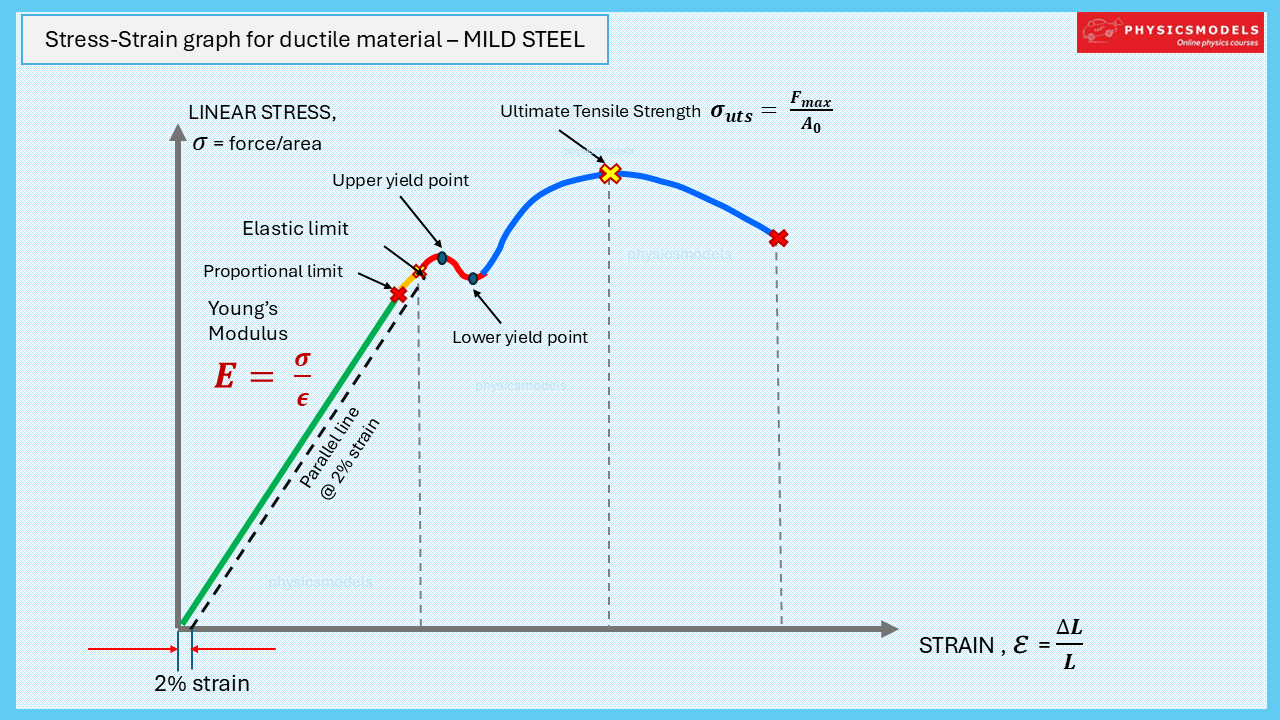

The doubt arises – The answer is : Yes, to an extent, metals when pulled apart in tension or compressed will come back to their original form, provided the stress is limited to a zone. For understanding this fully, we have to see the Stress-Strain graph for that perticular metal

- Linear Stress = Force per unit area, or {F/A} ] , where the Force acts axially along the centre line on the cross-section of the metal.

- Linear Strain = {increase in length)/(original length)} or Δl/L . This is like pulling a rubber band , the dimensions are measured axially along the centre line on the cross-section of the metal.

- The net result of either pulling apart, or compressing , will depend on the metal property, as given by where we are on a graph of Stress versus Strain.

Below image is like a simple tabletop experimental setup. A cylindrical rod (or it can also be a wire) made of some metal like steel, is held rigidly at two ends on a block such that when we move the blocks apart, with a big enough force, the rod will have to elongate, it has nowhere else to go.

Remember, the holding blocks slide horizontally on the green base (Baseplate of machine), perfectly parallel to the central axis of the rod.

- Tensile force and tensile stress: comes into play when the right side block moves to the right, keeping the left side block fixed on baseplate

- Compressive force and compressive stress : comes into play when the right side block moves towards the left side block.

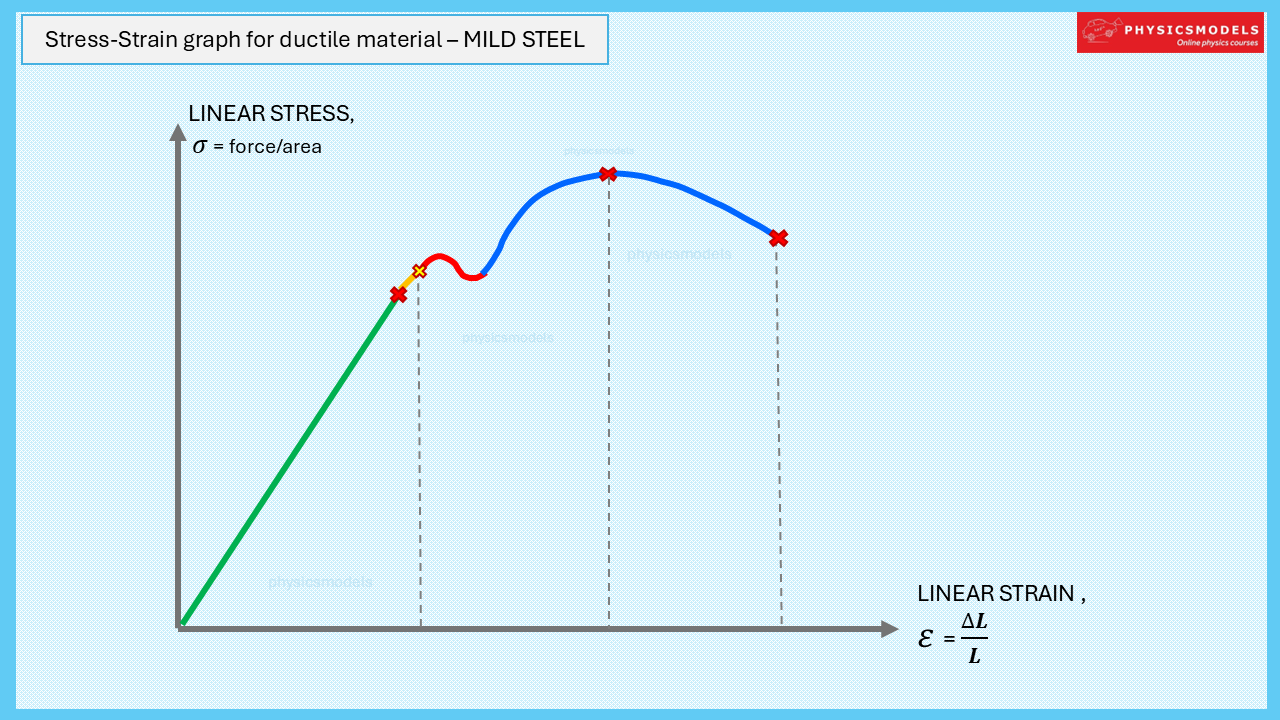

Once the Force starts acting on the rod, the beautiful graph kicks in….the very well-known stress-strain graph. Below is a teaser, a beginning, as we go deep into the graph in a later section of this course. Anyway, if there is a QUIZ, you can say confidently that the material must be a DUCTILE material, since when force is applied, the metal expands gradually , shown by strain values on the horizontal axis. The metal does not have a sudden fracture. (If it suddenly fractures, like a bone in our body, then it is called a BRITTLE material)

Note: Initial graph, more details follow

More on the graphs in a separate section

The amount of extension for a metal won’t be as long as for a rubber band, the increase in length will be very small, and the force required to elongate a metal wire or bar will be huge. But in the end, if the Force is not too large, the metal wire/bar can come back to its original shape. (provided the elongation is within a limit ) . That meets the elasticity definition.

If a metal is deformed beyond a particular stage, it would remain deformed and won’t bounce back to its original shape. This behaviour (story) can be explained by a graph of Stress versus Strain.

DUCTILE versus BRITTLE MATERIALS

The stunning visual below shows a BRITTLE fracture of cast iron. The plate has simple sheared off, like butter cut by a knife.

On the other hand, DUCTILE fracture will be gradual, and extended.

1st stage : Elastic Deformation : Only till Elastic Limit. If force is released now, material will come back to original length.

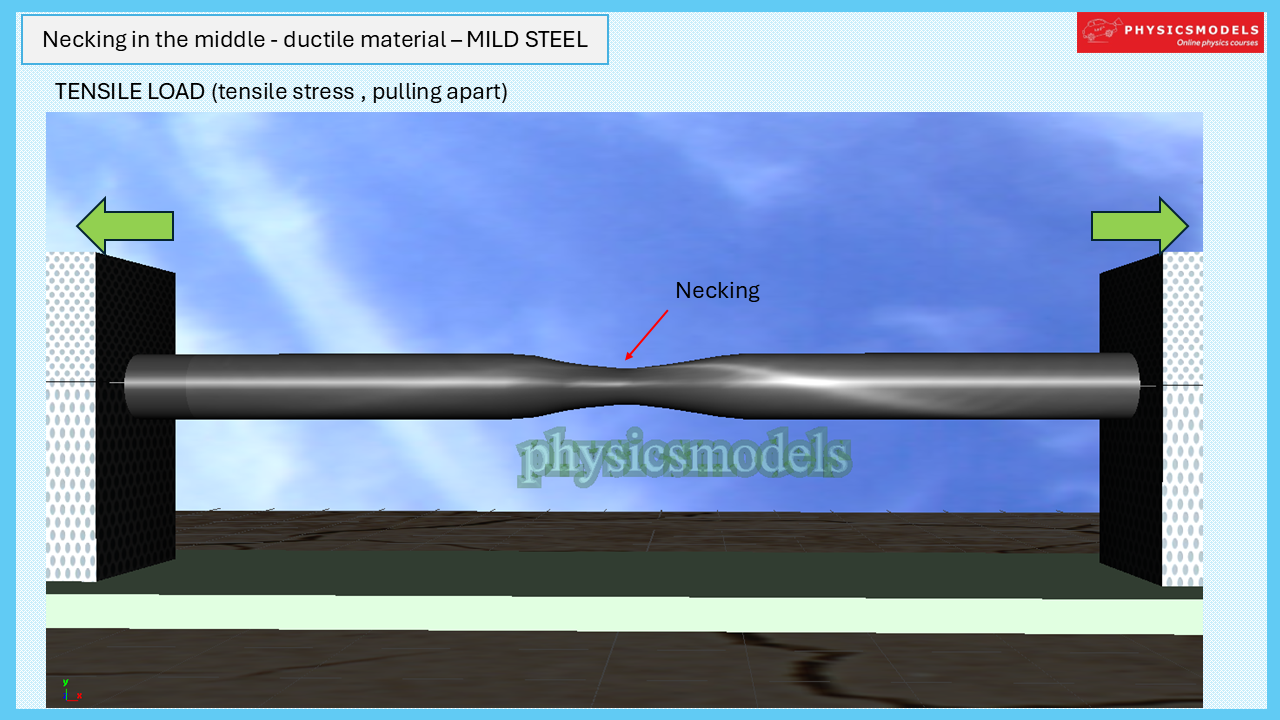

2nd stage: PLASTIC deformation : see graph. This is called Necking Region. In plastic deformation region, when Load (Force) is applied, the rod stretches and Stress actually decreases, we cannot increase stress even if we want to do that. The material breaks into two pieces, this is called RUPTURE.

Do an experiment and pull a cylindrical piece of atta (flour). The flour becomes thin at the centre and separates if we keep pulling it.

The beautiful image below shows Necking very clearly.

NECKING becomes the weakest link. The rod elongates more, neck becomes even smaller, and finally the neck becomes so small that the two halves separate out . This failure stage is called DUCTILE FAILURE, see physicsmodels image below

PRACTICAL KNOWLEDGE – STUDY LITERATURE

Image courtesy- ASTM International, a highly reputed organisation. Observe how the cracks have started forming.

Another interesting image of a STEEL BOLT shows ductile failure, you should be able to judge this by just looking at the cross-section of the breakage zone.

Please note– Steel is a material that shows ductile behaviour, whereas Cast Iron is a material that shows Brittle behaviour.

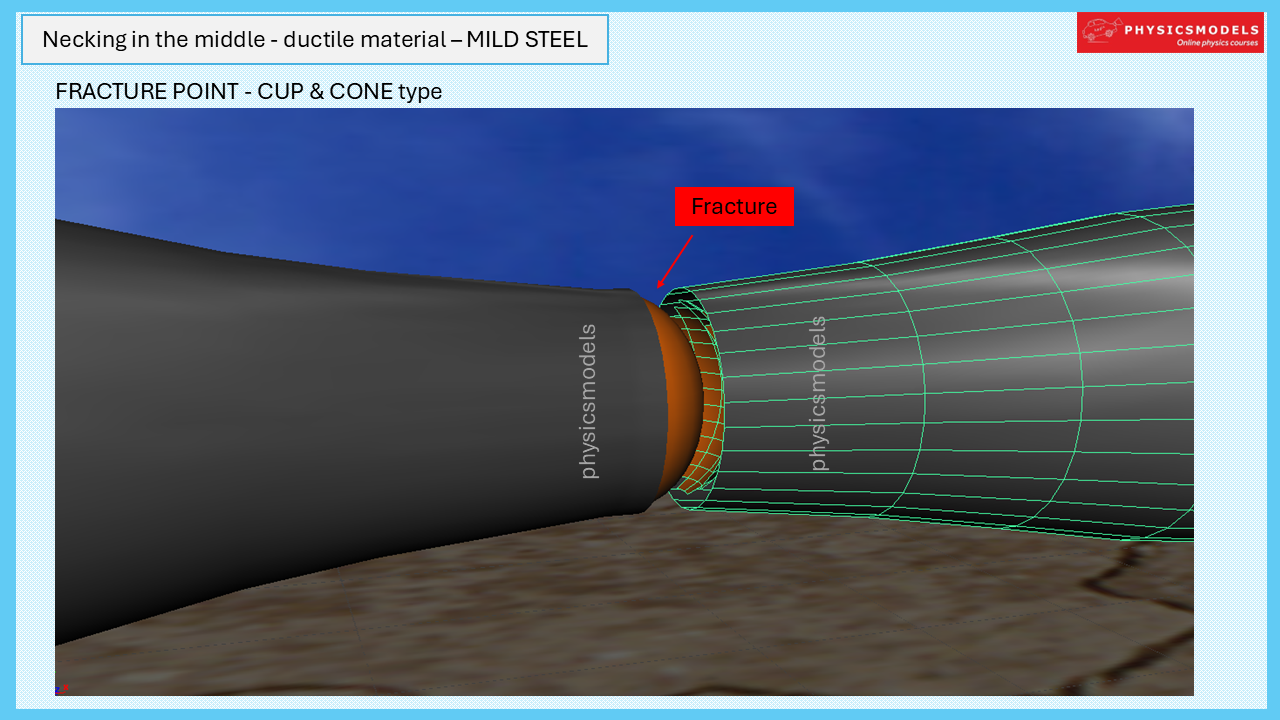

CUP and CONE FRACTURE – typical for ductile materials

Another Image below shows that after necking, the separation of the two halves look like a Cup and Cone at the ends. This is a proof of a gradual failure, proof that it is a Ductile material.

Another image below to help you understand the CUP & CONE failure mode of Ductile materials, such as MILD STEEL (LOW CARBON STEEL.)

Practical knowledge :

- Ductile materials: Low Carbon steels , also called Mild steels

- when you increase carbon % in steel material, when it tends to High Carbon steel , it becomes BRITTLE material.

Video and Animation :

we take an example of a metal rod, having a circular cross-section, and we put some Force along its length. The Force acting on its cross-sectional area causes STRESS , Stress is like a pressure, and = Force/(unit area of cross-section) . Stress acting along the length of the rod is called Tensile Stress. This if big enough, makes the Rod longer, and then if we release the Force and hence the Stress, see how the length comes back to its original length.

What is DEFORMATION?

The word deformation is commonly used, for anything that has changed in length , or shape from its original starting point. In particular, for a deformation in length/width direction, the word “tensile” is used , such as ” Tensile Elongation ” , “Tensile Stress” etc….

What is Elastic deformation and difference with Plastic Deformation?

- There is ZERO deformation of the material till the Proportionality Limit. The graph is a perfect straight line, and Hooke’s Law is valid all along the straight line. But Hooke’s Law is not applicable after the Proportionality limit. Even Elastic Limit is not coming under Hooke’s Law.

- Elastic Deformation starts immediately after the stress cross the Proportional Limit on the stres-strain graph .

- Elastic deformation is defined as the deformation like increase in length for tensile forces, where the material can recover back to its original form or length IF the Force is released. That means upto Elastic Limit.

- Plastic deformation starts after Elastic Limit, covers Yield Points Upper and Lower, the Ultimate Tensile Strength point, and upto Fracture.

- The difference between Elastic Deformation and Plastic Deformation is that in plastic deformation, the material will not come back to its original shape. It dooes’nt yet reach its breaking point, but it has changes shape or length permanently without breaking. This happens in the region of the graph after the Elastic Limit (and before the final breaking point)

Image of a permanent deformation:- The image below shows a cylinder (round cross-section) that has been permanently deformed by a large force, this cannot go back now to its original shape. We say this has gone beyond its elastic limit.

Area of cross-section: This is important to note since the force of elngation is acting all the time on this cross-section. Force / area is pressure, and in elasticity, it’s called “stress”. Like in above image , the area of cross-section of a metal bar or rod may reduce and become thinner when elongated beyond a point . But for small elongations, like in animation shown , the area of cross-section can be considered to be constant.

Also, the proportionality of Force and elongation holds only for a small range, upto elastic limit. Hence, for Hooke’s Law and applying Young’s Modulus, the Law states an assumption that “provided the deformation is small“.